|

Safety Emporium is a proud sponsor of this site. |

|

Home Page --> Burners and Torches

|

|

Safety Emporium is a proud sponsor of this site. |

|

Home Page --> Burners and Torches

|

A wide variety of glassworking torches and burners is available to the glassblower. The selection shown here is representative of the burners and torches found in a typical scientific research glassblowing shop, but many other variations exist.

The gases commonly used for working borosilicate glasses are propane or natural gas mixed with oxygen. It is important when selecting your burner, torch and tips that they be designed for use with these gases. Units designed for gas/air mixtures should not be used with gas and oxygen.

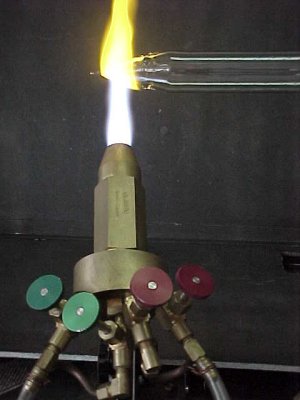

A typical glassblower's burner. Burners are usually bench or lathe mounted. The bench burner shown here has two gas and two oxygen valve controls, offering a wide variety of flame configurations. The aluminum collar shown mounted on the burner barrel aids in heat dissipation.

Another example of a glassblower's bench burner. The two inner valves (green = oxygen and red = gas) create a relatively small tight flame. Opening the two outer valves offers the glassblower a much larger flame as shown here.

In use, burners are usually stationary or mounted as part of a fixture. The glass is brought into the flame where it is heated and manipulated by the glassblower.

Lathe burners are mounted on a movable carriage. The four (4) jet burner pictured can be moved up or down to match the diameter of the glass being worked or rolled back and forth along the length of the glass tubing using the carriage. Each burner jet angle may be adjusted as well.

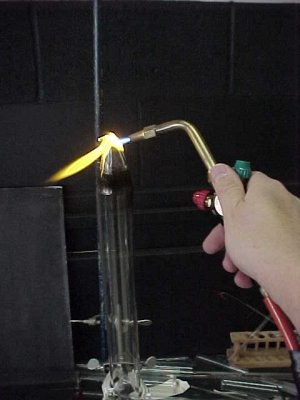

Glassblowing torches are usually smaller and much lighter than burners or burner assemblies. The torch shown here is a pre-mix (gas/oxygen are mixed in a chamber within the torch body) style quite popular with many glassblowers.

Pre-mix torches often have removable tips in a wide range of sizes, providing a number of flame options to the glassblower.

Torches are brought to the glass, which is held stationary by clamps or other fixtures. The size, weight and balance of a torch are important features to the glassblower.

Torches and burners come in a variety of shapes, sizes and capabilities to fill the many applications required by the glassblower. Traditionally, these are made of metals such as stainless steel, brass, etc., however, special needs may require custom fabrication using non-traditional materials. For example, if metal contamination from a hot torch might cause problems in a particular application, one can use a glass (quartz) torch. Additional photos and information may be found at Blue Flame Technology

Disclaimer: Glassblowing has inherent hazards that can result in burns, cuts, injuries or even death. While every effort has been made to convey best safety practices, the materials presented herein can not anticipate every possible risk or hazard associated with a given glassblowing activity. The reader is responsibile for assessing and mitigating any and all such hazards or risks before commencing any activity connected with his or her use of these materials. Neither the author nor ILPI assumes responsibility or liability for injuries, losses, claims or damages to the reader or other parties that may result from the use or misuse of these materials.

by Joe Walas and/or ILPI, all rights reserved unless otherwise stated. Unauthorized duplication or posting on other web sites is expressly prohibited. Send suggestions and comments (include the URL if applicable) to us by email.