Find all of your laboratory and workplace safety supplies at Safety Emporium!

Energy Units |

Glossary Index |

EPCRA |

| MSDS Topics |

Free Sites | FAQ's | Regulations | Glossary | Software | Suppliers |

| Books | Forum | Poll | Fun stuff | Quiz | Store | |

| Understand your MSDS with the MS-Demystifier | Search ALL our MSDS info | |||||

Engineering controls eliminate or reduce exposure to a chemical or physical hazard through the use or substitution of engineered machinery or equipment. Examples include self-capping syringe needles, ventilation systems such as a fume hood, sound-dampening materials to reduce noise levels, safety interlocks, and radiation shielding.

When substitution of hazardous chemicals or processes is simply not possible, additional measures to control employee exposure need to be taken.

While personal protective equipment (PPE) such as respirators can help protect an individual from a hazardous material, engineering controls protect all workers by reducing or eliminating the hazard. For example, someone who is spray-painting can wear a respirator to avoid inhaling toxic fumes, but nearby workers without any respiratory protection will be exposed. Through the use of proper local exhaust ventilation everyone can be protected.

In fact, the OSHA standard on Air Contaminants, 29 CFR 1910.1000, requires the use of either engineering or administrative controls if any such controls are feasible:

"...administrative or engineering controls must first be determined and implemented whenever feasible. When such controls are not feasible to achieve full compliance, protective equipment or any other protective measures shall be used to keep the exposure of employees to air contaminants within the limits prescribed in this section. Any equipment and/or technical measures used for this purpose must be approved for each particular use by a competent industrial hygienist or other technically qualified person. Whenever respirators are used, their use shall comply with 1910.134.

Likewise, the US Environmental Protection Agency has recently drafted a change to its risk determination for methylene chloride to reflect the reality that PPE is not always and appropriately used when it should be. Not assuming use of PPE in its baseline exposure scenarios reflects EPA's recognition that certain subpopulations of workers exist that may be highly exposed because they are not covered by OSHA standards, whose employers are non-compliant, or because OSHA's chemical-specific Permissible Exposure Limits (largely adopted in the 1970's) are described by OSHA as being "outdated and inadequate for ensuring protection of worker health". Should this draft change make it to the final rule, one should expect to see this reasoning applied to all chemical risk assessments moving forward.

Note: In certain circumstances, administrative controls can be successful in controlling employee exposure to contaminants; e.g., maintenance operations involving toxic substances can sometimes be performed at night in the absence of the usual production staff (but not to comply with the PEL of OSHA-regulated carcinogens).

Encourage use of proper hearing protection with electronic decibel meter signs from Safety Emporium.

This does not mean that engineering and other types of controls (including PPE) are mutually exclusive. Employers may need to use multiple types of overlapping controls to prevent employee overexposure. Also note that the degree to which engineering controls are required depends on the particular standard. For example, 29 CFR 1910.95(b)(1) Occupational Noise Exposure, allows employers to rely on personal protective equipment (PPE) and a hearing conservation program rather than engineering and/or administrative controls if hearing protectors will effectively reduce the noise hazard to acceptable levels.

OSHA considers economic feasibility to be a major issue with engineering controls. Requirements that would threaten the economic viability of an entire industry cannot be considered economically feasible under the OSH Act. OSHA may permit PPE in lieu of engineering controls (at least until engineering controls become a less significant burden for the company) when all of the following apply:

When employers complain that implementation of engineering controls will present an unbearable economic burden, they must present evidence that addresses the reasonableness of the estimated costs of engineering or administrative controls. This includes installation, maintenance, and lost productivity, as well as their progress compared to their industry peers. The evidence may also include the relative costs of engineering or administrative controls versus PPE.

In those limited situations where there are no feasible engineering or administrative controls, full abatement can be allowed by PPE.

Ensure a safe workplace with antislip floor marking signs from Safety Emporium.

NOTE: We may collect a share of sales or other compensation from the links in the following list:

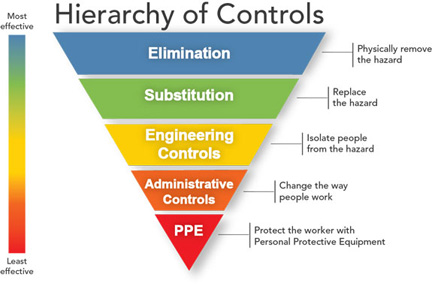

Engineering controls typical appear in Section 8 (exposure controls/personal protection) of a Safety Data Sheet. Regardless of what the SDS states, always remember that the The preferred methods for reducing chemical exposure, in order of general effectiveness, are illustrated in this diagram:

Specifically, these steps are:

Engineering controls may receive specific mention on SDS's. For example, when a material has a low PEL, there may be a section explicitly labeled "Ventilation requirements". Specific machinery may be recommended - or perhaps specifically discouraged. For example, ductless recirculating laboratory hoods might not provide sufficient protection from certain highly toxic materials; in these cases a properly vented fume hood (perhaps outfitted with a scrubber) would be required.

Two of the most common engineering controls found on an SDS are local exhaust and general ventilation. There are dozens of types of engineering controls.

When working around hazardous sources of energy, OSHA requires the use of lockout devices like this one from Safety Emporium.

See also: administrative controls, fume hoods, respirators, personal protective equipment (PPE), ventilation.

Additional definitions from Google and OneLook.

Entry last updated: Sunday, July 24, 2022. This page is copyright 2000-2025 by ILPI. Unauthorized duplication or posting on other web sites is expressly prohibited. Send suggestions, comments, and new entry desires (include the URL if applicable) to us by email.

Disclaimer: The information contained herein is believed to be true and accurate, however ILPI makes no guarantees concerning the veracity of any statement. Use of any information on this page is at the reader's own risk. ILPI strongly encourages the reader to consult the appropriate local, state and federal agencies concerning the matters discussed herein.