|

Safety Emporium is a proud sponsor of this site. |

|

Home Page --> Glass Strain and Annealing

|

|

Safety Emporium is a proud sponsor of this site. |

|

Home Page --> Glass Strain and Annealing

|

| Scientific glassblowing is the fabrication of scientific glassware and uses a torch or burner. The flame is adjusted to varying degrees of sharpness, ranging from a pinpoint for precision work, to a large bushy flame used for heating and forming broad areas. This process of heating, forming and cooling will introduce strain (often referred to as stress) into the glassware. Invisible to the naked eye, the strain is nevertheless present and is a potential point of failure in the glass apparatus unless relieved.

|

|

|

The degree of stress will be determined by a number of factors including the intensity and size of the torch flame, glass wall thickness and the complexity of the seal itself. The severity of the stress may be enough to cause glass failure - sometimes while the glass piece is under construction! Many glassblowers hand-anneal the work during the fabrication process, with full furnace annealing prior to customer delivery. At no time should un-annealed glass apparatus be put into laboratory service. |

| Glassblowers us a device called a polariscope to help detect the presence of glass strain. By looking through two polarized filters held in varying orientation one can visualize the stress patterns in a piece of glass. An excellent and detailed explanation of glass stress, strain and polarisers is found in the Manual of Scientific Glassblowing (ISBN 0 9518216 0 1) published by the The British Society of Scientific Glassblowers but is apparently out of print. They did offer it on their web site at one time, but now the only place you can find it is an apparently incomplete version on the Internet Archive Wayback Machine:

This item may still be available from the BSSG on CD for a small fee. We are told that it is being supplanted by a rather affordable new work Laboratory Scientific Glassblowing: A Practical Training Method by Paul Le Pinnet which is slated for release on May 21, 2017. |

|

|

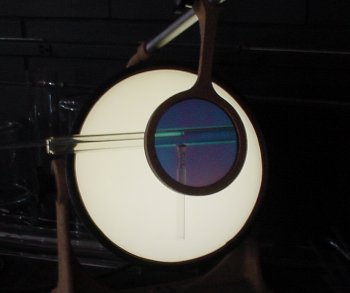

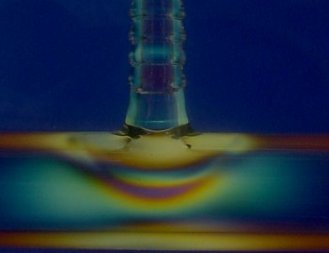

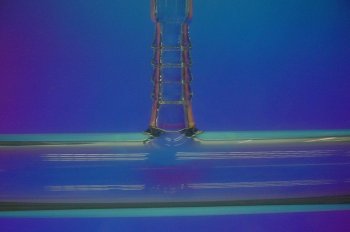

The polariscope contains a light source in the base that houses one of the polarizing filters. The second filter is housed in an adjustable holder (the smaller diameter window pictured here). Polariscopes are available in many forms, including battery operated as shown directly above. The two close-up photographs below are samples of a typical stress pattern produced when making a "T" seal. This seal is normally made by holding the torch flame stationary, blowing out a hole in the main glass body to match a second tube (hose connection in this example). The stress pattern mimics this heat zone - compare these pictures to the one of this piece as it was being made at the top of the page. Color and line intensity can be changed by rotating one of the polarized filters, so caution is advised when "reading" the viewer. It is best to assume that the polariscope reads only stress - not necessarily the degree or intensity of the stress. |

|

|

| Relieving stresses in the glass can be performed by hand annealing, which is a process of using a torch flame of diminishing intensity and size over time, slowly and evenly allowing the glass to return to room temperature. An alternative is to use a glass annealing furnace. The bell-type furnace shown here is programmable to allow pre-determined ramps up to the annealing temperature(s) and then back down to room temperature. |

|

|

Here we see the same T joint we saw above, but now it has been annealed. As you can see under the polariscope, there is little strain remaining in the finished product.

The nitty-gritty details of the physics behind the operation of polarisers and methods for measuring strain in glass can be found at QuinVision. Polarisers are commercially available and are relatively easy to build yourself. |

The Corning Museum of Glass has a web page with an excellent and engaging video that demonstrates stress in unannealed and properly annealed objects.

This page and any associated material is copyright 2002-2025 by Joe Walas and/or ILPI unless otherwise stated. Unauthorized duplication or posting on other web sites is expressly prohibited. Send suggestions and comments (include the URL if applicable) to us by email. CAUTION: Be sure to read this important safety/legal disclaimer regarding the information on this page.